All-Bin Flex Skirt

Click on pictures above for additional photos/enlargement

Never again deal with water seeping under your bins, rotting your grain and rusting your bins.

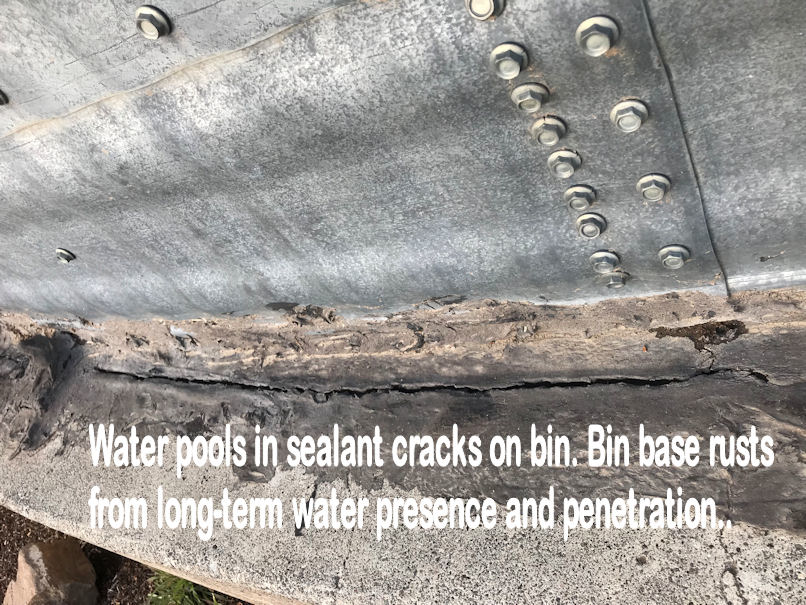

Grain bins expand and contract with heat and cold, cracking sealants. There is constant conflict between concrete foundation and grain bin base, continually damaging any type of sealant applied.

Input your bin(s) information on the form below and get a quick quote! Multiple Bins? Quantity discounts will be applied to your quote. Our Flex Skirt information is below quote form.

Tar, epoxy and foam are expensive fixes that don’t last. Inevitable cracks appear in these temporary “band-aids,” even acting as reservoirs to store the water, rot the grain and rust the bottom of the bin rings. Sealants are an expensive, labor intensive, counter-productive and temporary fix.

Beginning in the Pacific Northwest and now stretching across the country, our Flex Skirt is attached to bins as small as 15′ in diameter up to diameters as large as 106′! Our customers no longer deal with rotten grain and rusty bottom rings!

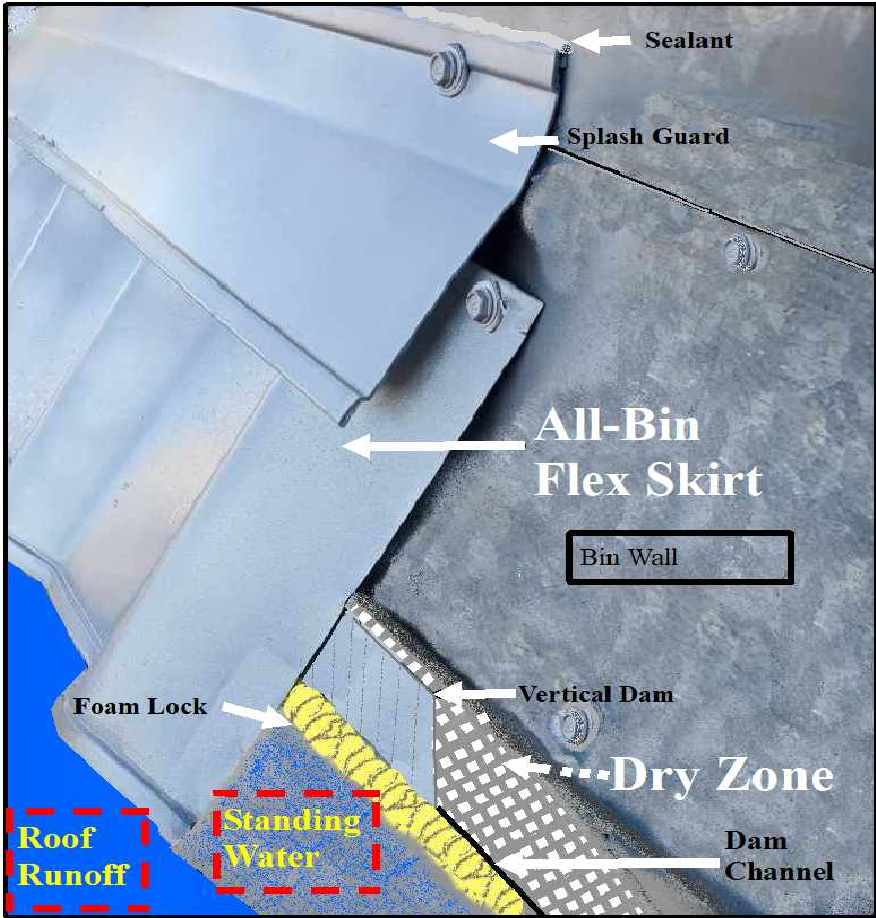

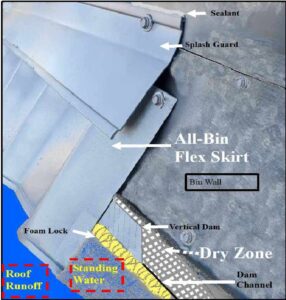

Bin owners now have a solution to this never-before solved problem. The Flex Skirt provides a dry zone. The skirt moves with the bin and the dry zone remains stationary and independent, protecting your grain and base rings at all times.

Even bin owners with elevated floors utilize the Flex Skirt so their bin bottoms and interior spaces always stay dry and rust free. The Flex Skirt keeps water outside the bin and dry zone. Bugs no longer have wet grain fines to flock to and multiply inside on the concrete floor. Without the rotting wet grain fines, bins are much less likely to corrode and rust.

The All-Bin Flex Skirt is attached to the bin and slides over the concrete base and essential protective dam as the bin expands and contracts, providing constant protection. Our protective dam and foam lock does not contact the moving bin, thereby maintaining dry conditions at the bin base at all times.

This was our first installation. Most concrete bin bases from bin wall to concrete edge are larger than 4″ which makes skirting to the edge prohibitively expensive. Our protective foam and dam (under the skirt) keeps water from flowing back to and under the bin wall.

Bin skirt testimonials

“We noticed our fairly new bins with elevated floors were rusting out where the bin and the concrete meet. It looked like it was going to be a very short-lived existence for these grain bins. We put the Flex Skirt on all our bins. We have solved our problem.” Mike Wiesler, Rocking MT Farms, Washington

“I looked for a solution to keep rainwater out of the bin I am using for a studio and happened up the Flex Skirt. The last think I need is water creeping into my studio. The skirt was easy to install per instructions provided and proved to be the perfect solution to keep water and moisture away from the property.” Ken Robbins, Kentucky

“I’ve been very pleased with the performance of the Bin Skirts. They have resolved an ongoing issue of leaks in my bins. Thank you!” James Wells, Nebraska

“We’ve always had a problem with water getting into the bins. These skirts are working great! I love them!” Marty Kroupa, Kroupa Farms, Kansas

“This is a no-brainer! It’s a permanent solution for what used to be a constant problem.” Darrell Ottness, Washington Producers, Washington

Your price will include:

-

- Flex skirting, corrugated and double seamed on top and bottom edges

- Fasteners

- Splash Guard-seamed on top and bottom edges, sectioned underneath to fit any bin

- Splash Guard sealant

- Applicator molding guide

- Sheet metal vertical Locking dam and foam for locking dam

- Instructions

- On-call tech help as needed

If I have a narrow concrete apron around my bin, do I need your foam dam?

No, concrete bin-to-concrete edges that measure 4″ or less do not need the foam dam. The skirt can be placed over the edge giving water an exit off the Flex-Skirt. The foam and dam cost is not a significant part of the Flex-Skirt cost and your quote will not include them. However, make sure you have no concrete wider than 4″.Do I need the protective locking dam and foam on bin base-to-concrete edges measuring more than 4″?

Yes. If not, water will flow into your bin like it did in the old days! Our protective sheet metal dam and foam-lock process will insure your bin will stay dry.Does the wind affect the Flex-Skirt?

No, we have never had a problem with wind moving the skirt. There is a natural tension and wind deflection inherent in the Flex Skirt that keeps it pushed against the bin at all times.Do rodents nest under the skirt?

We have never had a report of rodents nesting and multiplying under the Flex-Skirt. If a problem should occur, it is simple to place poison or traps under the Flex-Skirt or in the ends.What do I get with the All-Bin Flex Skirt?

Moveit provides all components required and instructions needed to install our Flex Skirt on your bins. Our patented Foam Dam under the Flex Skirt has no contact or conflict with the bin and therefore isn’t susceptible to cracks and seal damage. The Foam Locked Dam is nestled under the Flex Skirt and not degraded by ultraviolet sun rays. The Flex Skirt, Dam, Splash Guard and Fan Channel are galvanized sheet metal and attach to the bin with Stainless Steel self-tapping screws which are provided.How long does it take if I install the Flex Skirt myself?

Flex Skirt installation time varies by size, configuration of bin and skill and speed of crew — Two workers can usually install a Flex Skirt package on a 34’ bin without outside stiffeners in less than 4 hours. Large operators put the installation up for bid or hire a crew. Installation time ranges from 2.5 minutes per lineal foot up to 4+ minutes. Very thick base rings on larger commercial bins, outside stiffeners combine with efficiency of crew are factors that determine install time.Do I need tools to install the Flex Skirt?

Yes, a few tools are needed—cordless drill, 5/16” (or 3/8″ nut driver for over .177″ bin wall thickness), cinch or tie-down strap for skirt installation. A small 1″-2″ brush or dauber for sealant above splash guard. Depending on the bin, an angle grinder & cutoff (skinny) wheel may be needed for alterations along with a 4″ masonry blade (for a small channel cut in concrete around bin to seal foam on). Old tar and sealants should be removed 1”-3” and bin wall. Circular wire brush/electric drill works best. Concrete should be clean, bare and dryHow is the Flex Skirt shipped?

For small orders, Fed Ex Ground. Larger orders shipped LTL (Less Than truckLoad) motor freight. Each order will receive individual rolls of approximately 50’ corrugated Flex Skirt combined for preferred handling plus extra skirt lengths to fill your order.Do I have to have anything special at my location to receive order?

Not for Fed Ex Ground shipments.For LTL (Less Than Truckload) palletized orders, a forklift or loading dock must be at destination location or additional charges apply.

Rodent control/food grade inspection doors are available, not expensive & easily installed. We have never found this step necessary but can be easily added later if desired.

We would prefer that you use this website contact button to communicate with us. We are very busy taking care of orders and customers. Usually within 24 hours after you submit a quote request, we will contact you by phone to answer any questions and fill your order. We would prefer to be paid by check (which can be arranged when we call with your quote and received by the time we have built your order) but we also accept credit cards with a 3% charge.

Canadian Patent Pending, US Patent 11102926

Send us your bin info so we can give you a quote and get your Flex Skirts built!